Current Location:HOME > Products > Chip Disposal Series

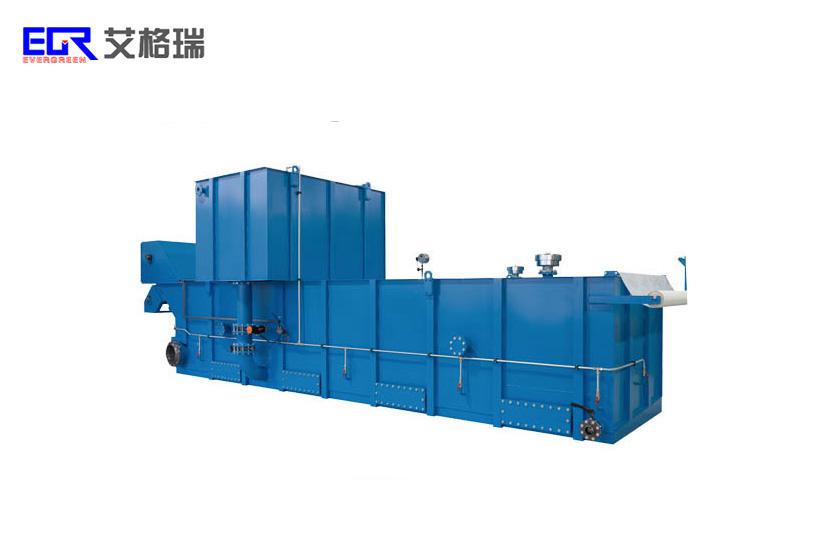

CP series magnetic chip conveyor

With its excellent performance, it has won high recognition in the market

-

Time:2025-05-04 12:38

-

Category:Chip Disposal Series

-

Application:Widely used in machine tools and automatic lines for various mechanical processing procedures of ferromagnetic materials.

-

+86-0535-6529899 (Hotline)

Details

characteristic:

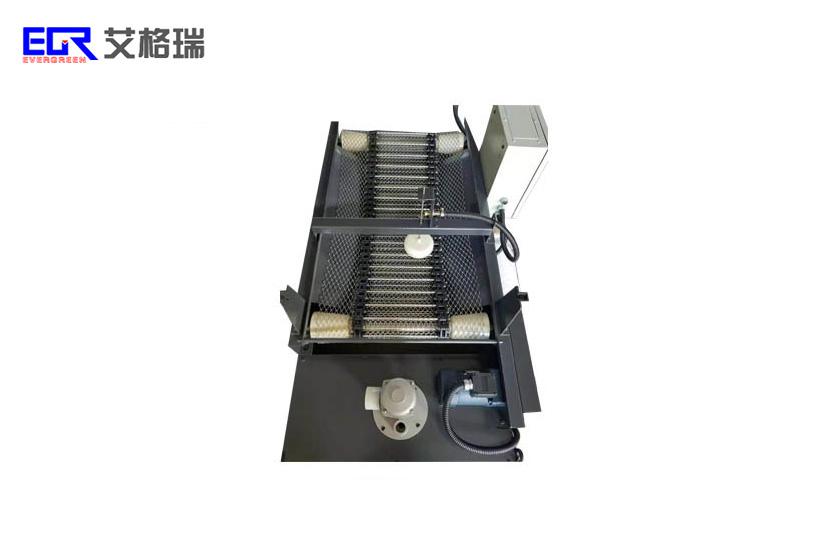

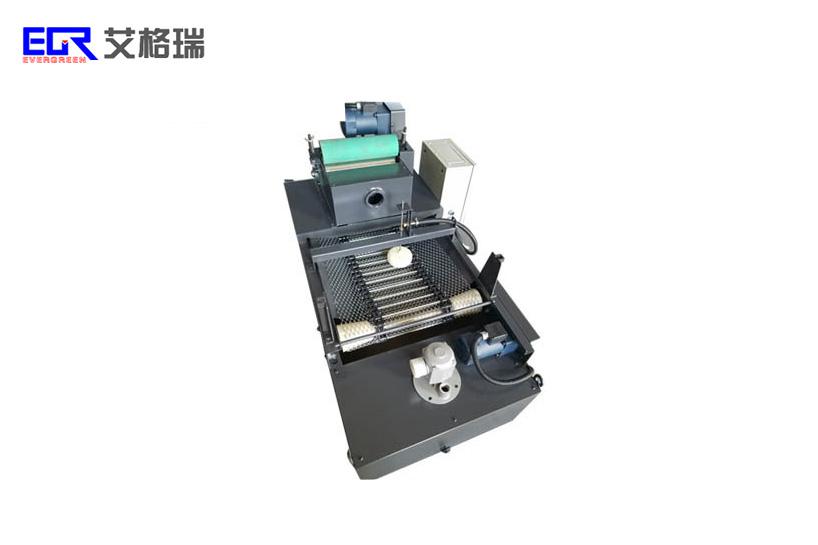

This device utilizes the strong magnetic field of permanent magnet materials to attract chips from ferromagnetic materials, and slides them on stainless steel plates to collect and transport chips (not applicable to chips larger than 100mm in length and in the form of clusters).

Purpose:

Widely used in machine tools and automatic lines for various mechanical processing procedures of ferromagnetic materials.

effect:

It is also an important chip removal device for separating ferromagnetic material chips in the coolant treatment system of water cooled and oil cooled machining machines.

Magnetic chip conveyor can handle various types of chips and can also be used as a conveying device for small parts of stamping and cold pier machine tools. It also has the characteristics of high conveying efficiency and a wide range of conveying speed options. The chain plate width of the magnetic chip conveyor is diversified, and the structural form is divided into seamless chain plate and slotted chain plate. Its streamlined design is beautiful and elegant, with smooth chip removal and overload protection function. Magnetic chip conveyor is widely used in CNC machine tools, combination machine tools, machining centers, specialized machine tools, assembly lines, automatic lines, and other chip conveying applications. It is also suitable for long-distance and equidistant chip conveying in large machine tools and production lines. Magnetic chip conveyor is a powerful tool for automated conveying, with small size and high efficiency. The magnetic chip conveyor has a high degree of serialization, universality, and standardization, with simple operation, reliable operation, easy disassembly and assembly, and easy maintenance. It can also be used in conjunction with other chip removal devices to form cutting treatment systems arranged in various forms.

Magnetic chip conveyor is widely used in various machining processes and automatic lines for processing ferromagnetic materials; It is also an important chip removal device for separating ferromagnetic material chips in the coolant treatment system of water-cooled and oil cooled processing machine tools; It can also be used as a conveyor and elevator for magnetic small parts, and is an ideal supporting equipment in the modern mechanical processing industry.

The four major characteristics of magnetic chip conveyor:

1. Adjust the spacing between each set of magnetic materials. The adsorption capacity of each group of magnetic materials is fixed and the amount of debris can be determined based on the delivery speed.

2. The magnetic chip conveyor should ensure the delivery of magnetic chips, debris, and powder chips with a length of less than 50mm. The coolant tank can be designed and manufactured according to the differences of cutting machine tools. The external dimensions of each part.

3. Commonly used for ensuring the delivery of magnetic chips in CNC machine tools, modular machine tool production lines, machining intermediates, and other cutting machine tools.

4. The divergent requirements of the host can be combined with other methods of chip conveyors and filters for use. The cooling oil delivery result is not ideal.