Current Location:HOME > Products > Filtering and chip removal equipment

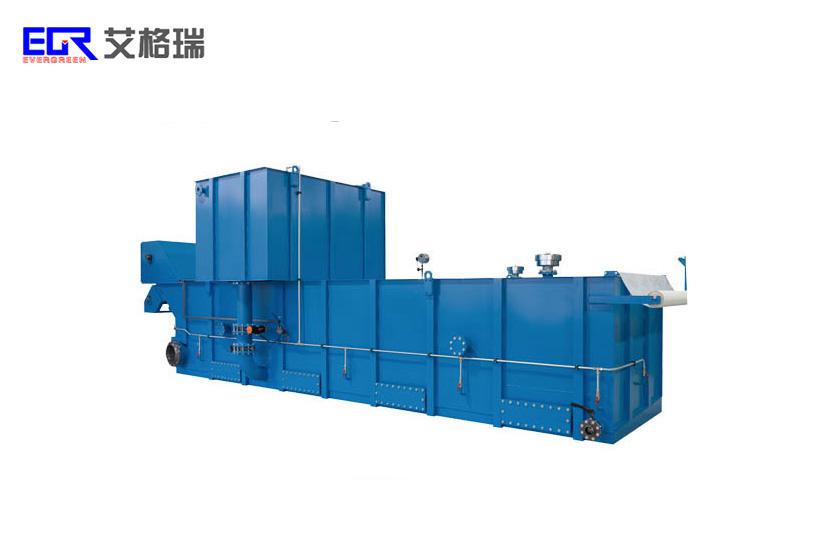

EGRGL2 magnetic roller paper tape filter machine

With its excellent performance, it has won high recognition in the market

-

Time:2025-05-04 12:10

-

Category:Filtering and chip removal equipment

-

Application:None

-

+86-0535-6529899 (Hotline)

Details

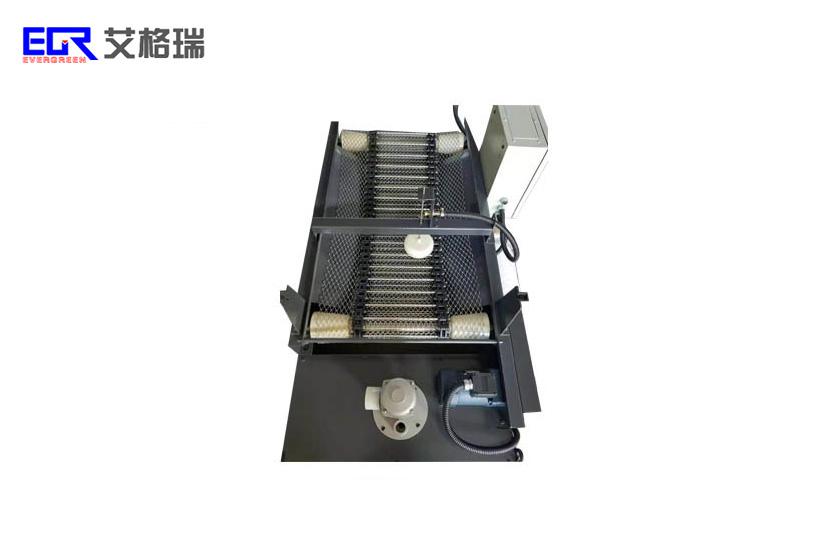

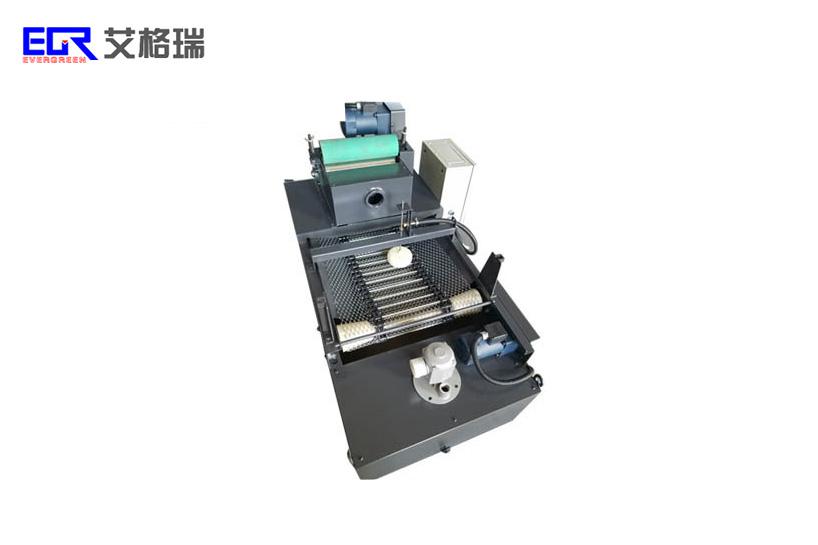

The EGRGL2 series magnetic roller paper tape filter adds a magnetic separator to the GL1 paper tape filter. During operation, most of the ferromagnetic impurities in the contaminated liquid are first separated by a magnetic separator to achieve secondary filtration, resulting in better performance and reduced consumption of filter paper.

matters needing attention:

When the ferromagnetic impurities in the contaminated liquid are debris, they can cause damage to the rubber roller components of the magnetic separator. In this case, a comb tooth magnetic separator should be selected.

2. When placing an order, it is necessary to confirm with our technical personnel the machine tool return method and the interface of the supply pump pipeline.

Paper tape filter machine is used for filtering coolant in metal grinding or other processing, and is also suitable for removing impurities from cleaning solutions, industrial water, organic solutions, and other solutions in the cleaning system of rough parts.

Precautions for operating the paper tape filter machine.

1. Before use, it is necessary to check whether the inlet and outlet pipes are installed properly, and fix the inlet and outlet pipes in the groove to prevent them from swinging easily.

2. Check whether the components and circuits of the paper tape filter are in place, such as whether the filter paper is flat, whether the power supply is normal, whether the inlet and outlet piping have been installed properly and fixed in the groove, and whether the inlet and outlet are not easily swayed.

3. Before starting the motor, check whether the voltage used and the motor wiring voltage are correct to prevent errors.

4. Before using the paper tape filter, check if the pressure gauge diaphragm is filled with clean water. Please fill it with water before locking the pressure gauge to maintain its accuracy.

5. Before starting the power supply, check whether the inlet and outlet pipelines are selected correctly, such as whether the inlet and outlet are open, whether the pipeline flow path is correct, whether the liquid in the medicine tank is normal, and whether the pipeline is damaged.

6. During the use of the paper tape filter equipment, it is necessary to check whether the operation is smooth. Within the previous week, each interface should be checked for leaks. Within the previous month, it is necessary to check whether the limit switch is working properly and whether the bearings are operating normally; Lubricate the chain once at the end of the month.

The workshop environment should be continuously ventilated to balance temperature and humidity. In the circuit of the paper tape filter, regular dust removal treatment should be carried out. Dust simply absorbs moisture from the air, and if not treated in a timely manner, it will pose hidden dangers to production.