Current Location:HOME > Products > Filtering and chip removal equipment

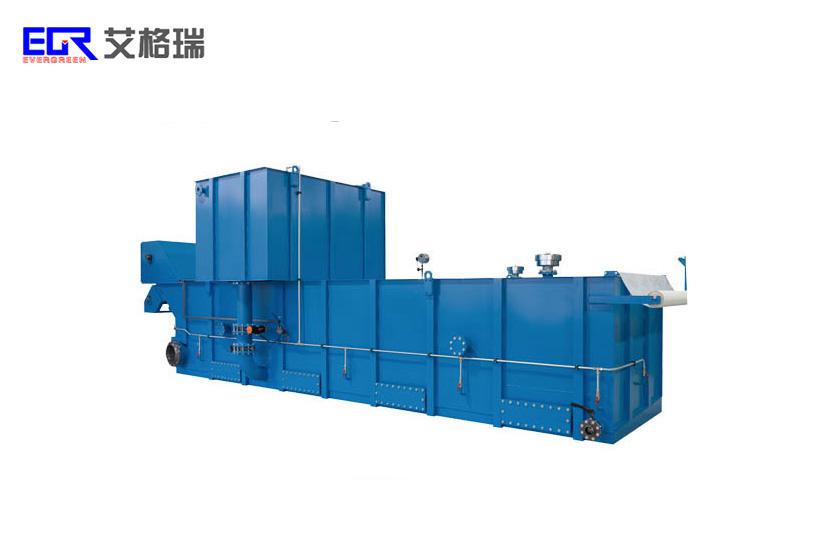

Hydraulic vacuum filter

With its excellent performance, it has won high recognition in the market

-

Time:2025-05-04 12:15

-

Category:Filtering and chip removal equipment

-

Application:None

-

+86-0535-6529899 (Hotline)

Details

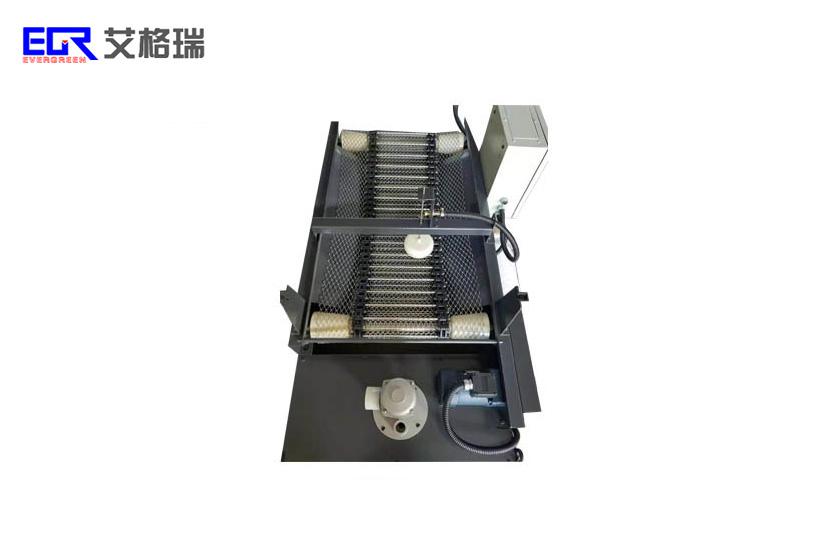

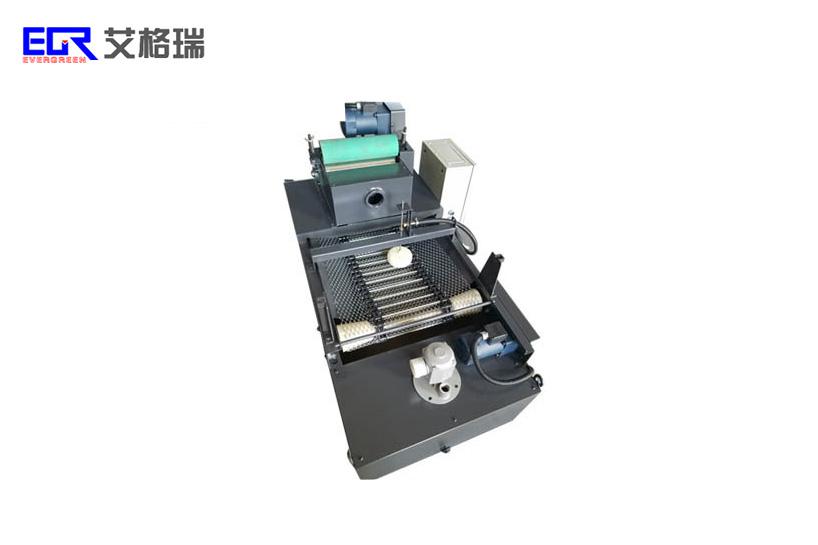

The vacuum negative pressure filter mainly relies on the suction of the filtration pump to increase the ability of liquid to pass through the filter cloth, isolate impurities to form a filter cake, and participate in filtration. The advantages of vacuum negative pressure filter are high degree of automation, good filtration accuracy, and higher utilization rate of filter cloth. It mainly consists of the following parts: drive reducer, dirty liquid tank, negative pressure chamber, liquid storage tank, filter pump, liquid supply pump, filter cloth and PLC, touch screen, etc. The dirty liquid tank chamber is connected to the negative pressure chamber through a filter plate and filter cloth. After the coolant containing impurities enters the dirty liquid tank, the filtration pump starts to work, sucking the clean liquid from the negative pressure chamber. The filter cloth isolates the impurities to form a filter cake. As the filter cake becomes thicker, the liquid's permeability decreases, forming negative pressure in the negative pressure chamber and increasing the liquid's permeability. This allows the dirty coolant to pass through the filter cloth and enter the negative pressure chamber, forming clean liquid. The clean liquid is stored in the storage tank and is pumped to the host by the supply pump. During this process, impurities are adsorbed on the filter cloth. When the filter cloth is severely clogged, the signaling system sends a command to drive the gearbox to automatically update the filter cloth, and the machine enters the next stage of the cycle.

Vacuum negative pressure filter is one of the useful filtering devices for filtering machine tool coolant. Generally, recyclable filter belts or disposable filter papers are used, with a filtration accuracy of 5-15 microns. The filtration accuracy of stainless steel wedge sieve is about 50-80 microns. The general flow rate is above 2000 liters per minute, suitable for the collection and filtration of cold and cold liquids in multiple machine tools. The gathering filtration system generally uses vacuum negative pressure filtration equipment in combination with pump supply system, pipeline system, liquid preparation system, and electrical control system.