Current Location:HOME > Products > Filtering and chip removal equipment

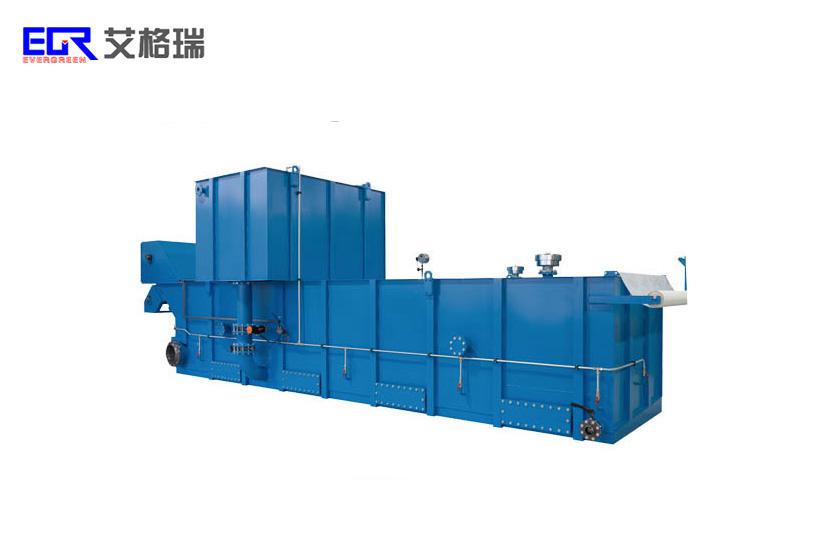

Hydraulic vacuum filter

With its excellent performance, it has won high recognition in the market

-

Time:2025-05-04 12:22

-

Category:Filtering and chip removal equipment

-

Application:Widely used in solid-liquid separation in metallurgy, chemical industry, environmental protection and other fields.

-

+86-0535-6529899 (Hotline)

Details

Product Overview:

Vacuum negative pressure filter is a solid-liquid separation equipment that plays an important role in modern industry. During the filtration process, the filter residue layer on the surface of the filter medium gradually thickens, and the resistance of the liquid passing through the filter residue layer increases, resulting in a decrease in filtration speed. When the filter chamber is filled with filter residue or the filtration speed is too low, stop filtering, clean the filter residue, and regenerate the filter medium to complete one filtration cycle.

Product features:

Can be used continuously, with high filtering efficiency and a coherent process. DCS is applied to achieve on-site and remote automatic control.

Product application:

Widely used in solid-liquid separation in metallurgy, chemical industry, environmental protection and other fields.

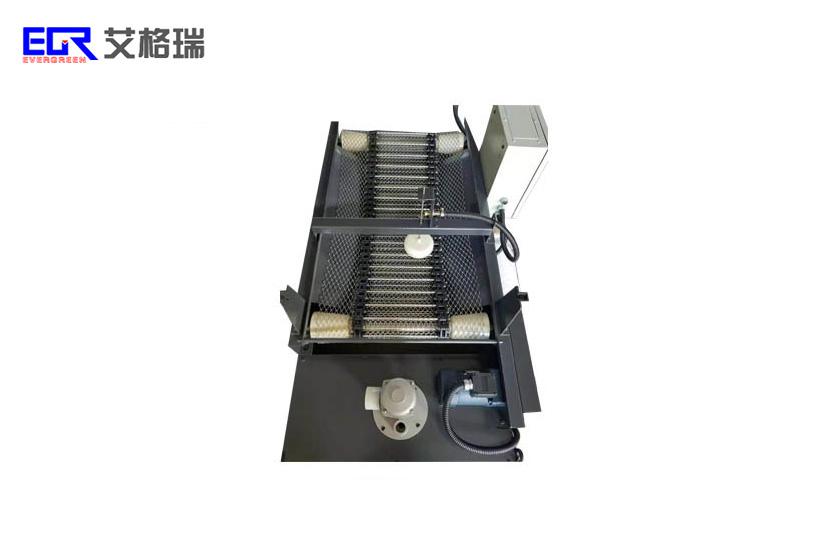

When the chips from the recoil scraper conveyor enter the drum scraper filter with the coolant, larger chips sink to the bottom of the machine and are scraped out by the scraper plate. Small particles are mixed in the coolant and block the filter mesh outside the rotating filter cartridge as the coolant passes through the filter cartridge. Due to the continuous rotation of the filter cartridge, the small particles clogged on the filter screen are washed down by the backwash cleaning series and scraped out by the scraper plate at the bottom of the machine. The filtered coolant flows into the clean liquid tank and is then pumped to the main engine by the liquid pump.

Performance and characteristics of recoil scraper chip conveyor:

1. Smooth operation and reliable work;

2. Has advantages such as high efficiency, long lifespan, and low operating costs;

3. Better than ordinary chain plate chip conveyors in wet processing;

4. Different filters can be replaced to meet the requirements of different customers and different filtration accuracies, with a filtration accuracy generally above 0.5mm;

5. It can achieve advantages such as automatic drum flushing, continuous filtration, maintenance free, and no consumables, fully meeting the cooling liquid requirements during processing;

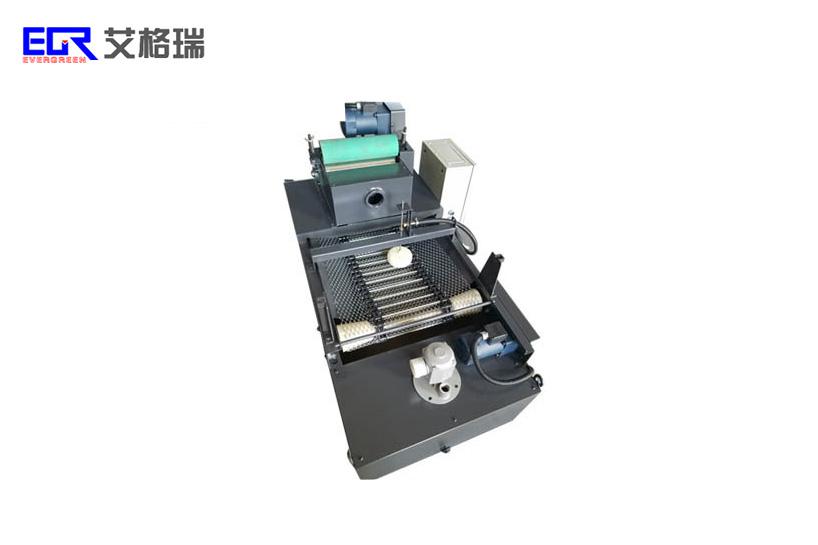

The recoil scraper chip conveyor is applied in various wet machining processes, suitable for conveying and filtering chips such as aluminum and copper, and for working conditions where the chip length is less than 50 millimeters, such as automotive cylinder head machining.

The filtration device of the recoil scraper chip conveyor is a comprehensive chip cleaning and purification cooling system developed by absorbing advanced technology on the basis of the original (magnetic) scraper chip conveyor. Suitable for various types of machine tools and machining centers with high precision requirements for cutting fluids, especially for conveying aluminum chips, cast iron chips, and broken chips. The characteristic of the recoil scraper chip conveyor is automatic drum cleaning and continuous filtration. High filtering accuracy, maintenance free, no consumables, can fully meet the filtering needs of chip flushing, spindle internal cooling, and tool cooling in machining centers.