Current Location:HOME > Products > Filtering and chip removal equipment

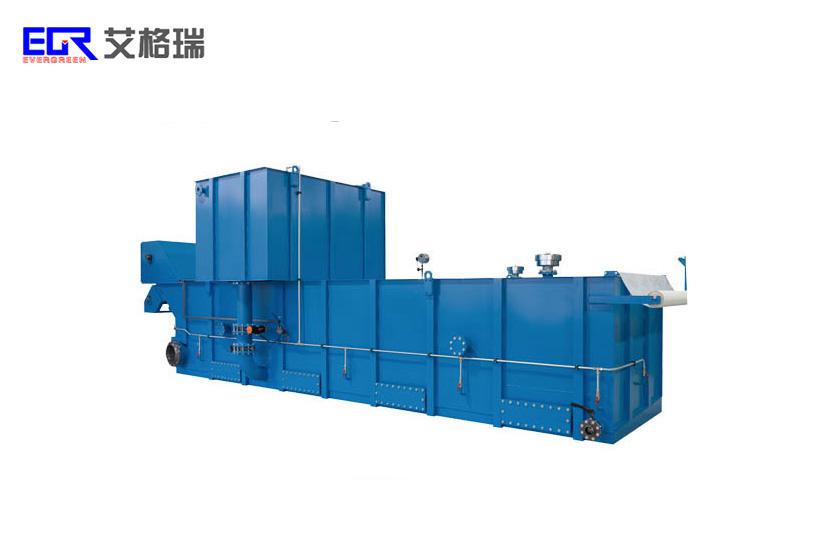

EGRGL1 paper tape filter machine

With its excellent performance, it has won high recognition in the market

-

Time:2025-05-04 12:12

-

Category:Filtering and chip removal equipment

-

Application:None

-

+86-0535-6529899 (Hotline)

Details

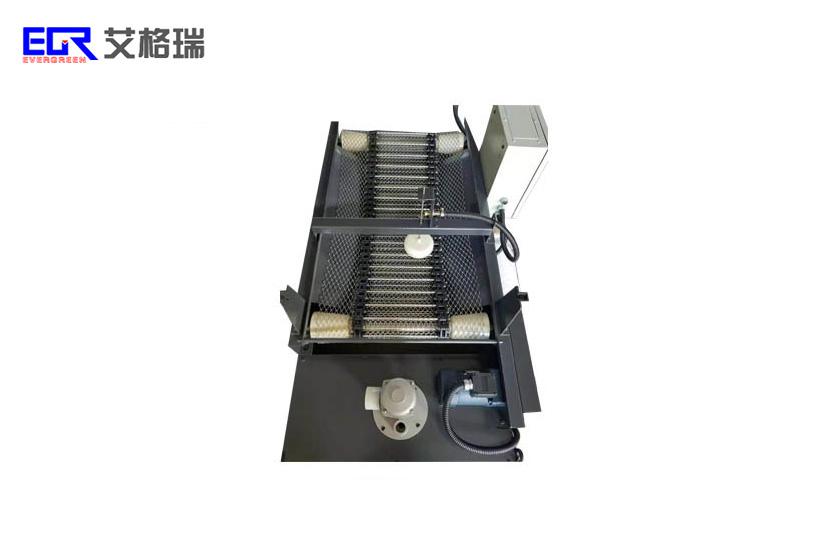

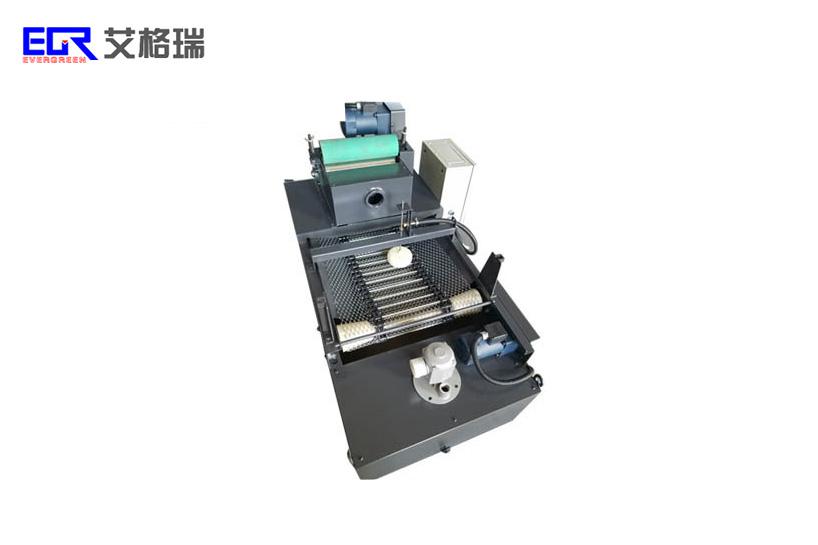

The EGRGL1 series paper tape filter machine consists of several parts, including a liquid tank, filter non-woven fabric (filter paper), transmission mechanism, transmission mechanism, supply pump, and collection tank.

When the machine tool is working, the return liquid enters the filter paper, and the transmission mechanism, wire mesh, and the filter paper laid on it form a curved surface. When the dirty liquid passes through the paper tape, impurities are adsorbed onto the surface of the paper tape, constantly accumulating, causing the liquid level of the dirty liquid to rise. The transmission mechanism sends a signal, and the motor drives the transmission mechanism to move. Impurities and dirty paper are discharged into the dirty box. After the paper tape is updated, the dirty liquid level drops, and the motor stops working. The next working cycle begins, and the clean liquid in the liquid box is transported to the machine tool by the supply pump.

This series is suitable for precision machining machines such as grinders and honing machines. Thermostats can also be equipped to meet the requirements of the corresponding operating conditions of the host.

matters needing attention:

When the shape of impurities in the filtered liquid is large, random bed reflux may cause damage to the filter paper and result in filtration failure; When the processing volume of the host is large and there are too many impurities, it will cause frequent clogging and replacement of the filter paper, resulting in severe consumption of the filter paper. The above two situations should be used in conjunction with other types of chip removal devices as much as possible, completing chip removal first and then filtering.

2. When placing an order, it is necessary to confirm with our technical personnel the machine tool return method and the interface of the supply pump pipeline.