Current Location:HOME > Products > Chip Disposal Series

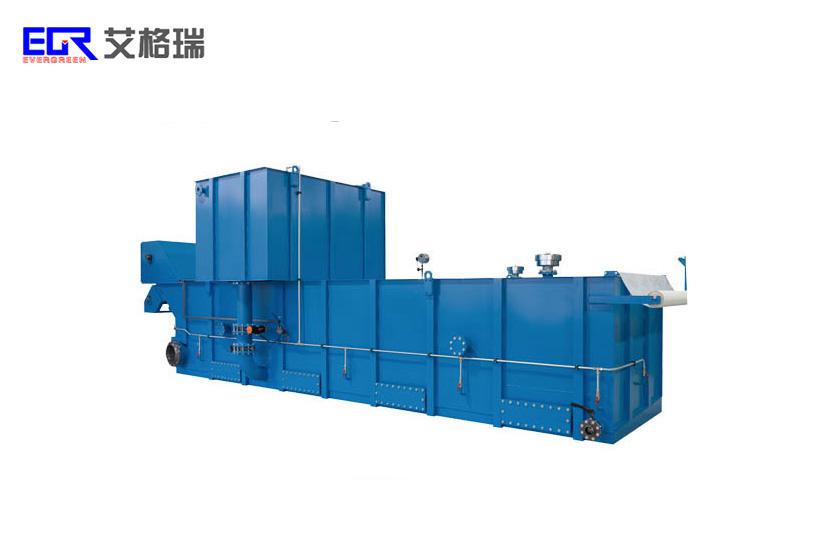

LP series chain plate chip conveyor

With its excellent performance, it has won high recognition in the market

-

Time:2025-05-04 12:36

-

Category:Chip Disposal Series

-

Application:Chain plate type chip conveyor is mainly used in various CNC machining centers and flexible production lines with high degree of automation. It can also be used as a conveyor for small parts of stamping and cold pier machine tools. It is also the main chip removal functional component of the coolant treatment system for modular machine tools.

-

+86-0535-6529899 (Hotline)

Details

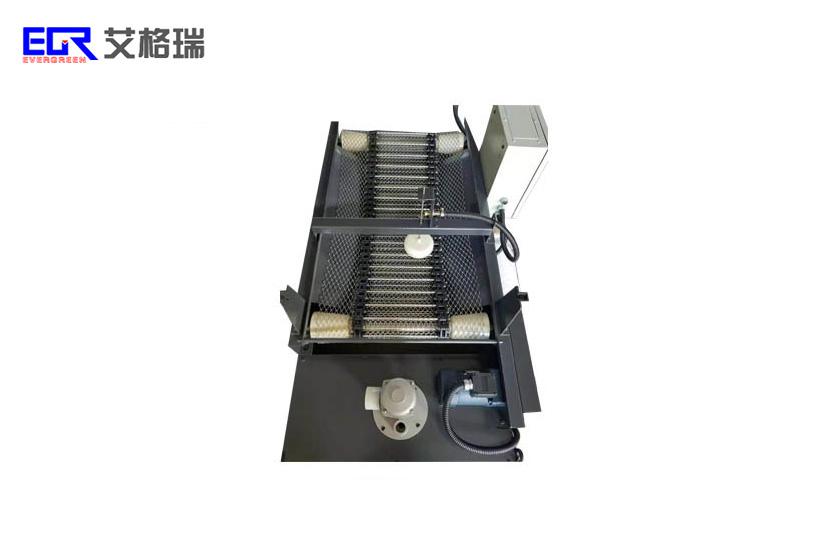

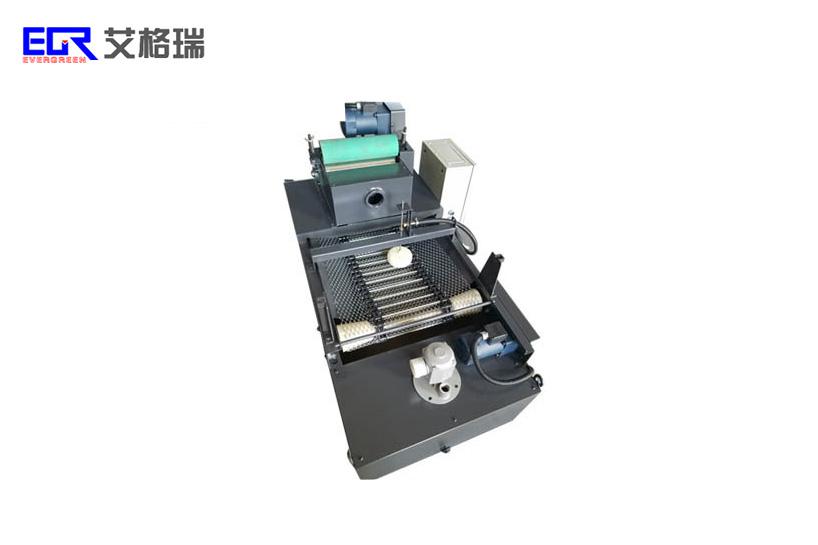

characteristic:

Electrical control can meet functions such as reverse, forward, and stop; Collect and transport various roll, ball, strip, and block shaped chips.

Purpose:

Chain plate type chip conveyor is mainly used in various CNC machining centers and flexible production lines with high degree of automation. It can also be used as a conveyor for small parts of stamping and cold pier machine tools. It is also the main chip removal functional component of the coolant treatment system for modular machine tools.

effect:

This device plays a role in improving the operating environment, reducing labor intensity, and enhancing the automation program of the entire machine.

Maintenance work of chain plate chip conveyor

1. The chain plate chip conveyor is not suitable for shutdown and full load start-up, and cannot be reversed.

2. The feeding of the chain plate chip conveyor should be smooth, and the large feeding size should be controlled within the specified range.

3. We also need to regularly check the bolt connections between the base plate and the chain plate, and promptly address any looseness.

4. Replace the lubricant 7-14 days after starting the reducer, and replace it every 3-6 months depending on the situation.

5. Each lubrication point of the chain plate chip conveyor should be filled with lubricating oil.

6. The tension of the traction chain should be appropriate. During the operation, regular checks should be conducted. If necessary, please adjust the tension adjustment screw of the component.

The deviation handling of the chain plate chip conveyor is carried out in three steps.

1. Check the deviation between the longitudinal centerline of the chain plate chip conveyor and the transverse centerline of the idler. If the deviation exceeds 3 millimeters, the installation holes on both sides of the idler gear set should be used to adjust the deviation. If the deviation is forward, then the deviation is backward.

2. Check the plane deviation of the tail bearing seat of the chain plate chip conveyor head. If it is greater than 1 millimeter, adjust two planes in the same meaning plane.

3. Check the position of iron filings during transportation. On the chain plate of the chip conveyor, iron chips are often transported out of the center, causing the chain plate to deviate. Therefore, when using, the material should be kept in the center position as much as possible.

The chain plate chip conveyor not only has stable performance, but also can effectively remove various debris. Chain plate chip conveyor is used for cutting chips in CNC machine tools, combination machine tools, machining centers, specialized machine tools, assembly lines, automatic lines, as well as the distance between large machine tools and production lines.