Current Location:HOME > Products > Filter and chip removal accessories

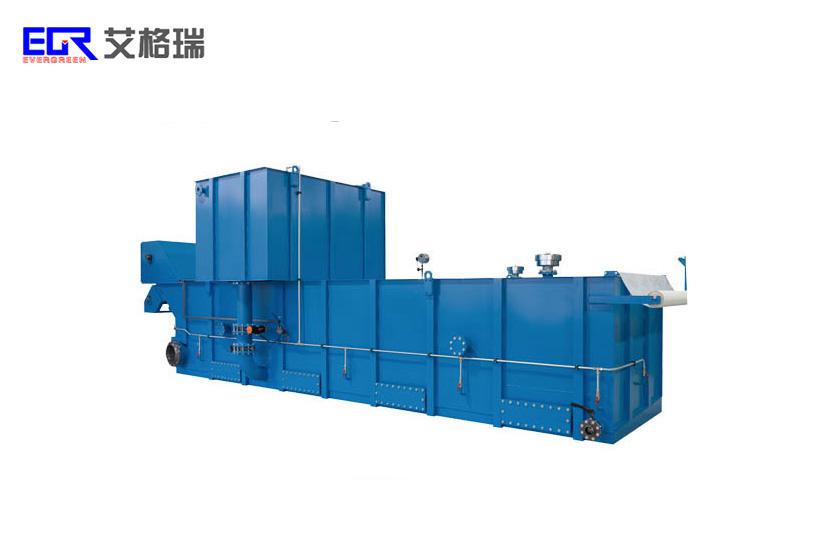

Eddy current separator

With its excellent performance, it has won high recognition in the market

-

Time:2025-05-04 13:45

-

Category:Filter and chip removal accessories

-

Application:Eddy current separators are mainly used to separate small particles in liquids, suitable for separating particles in high-speed grinding, strong grinding, general precision machining emulsions, and low viscosity oil-based cutting fluids.

-

+86-0535-6529899 (Hotline)

Details

characteristic:

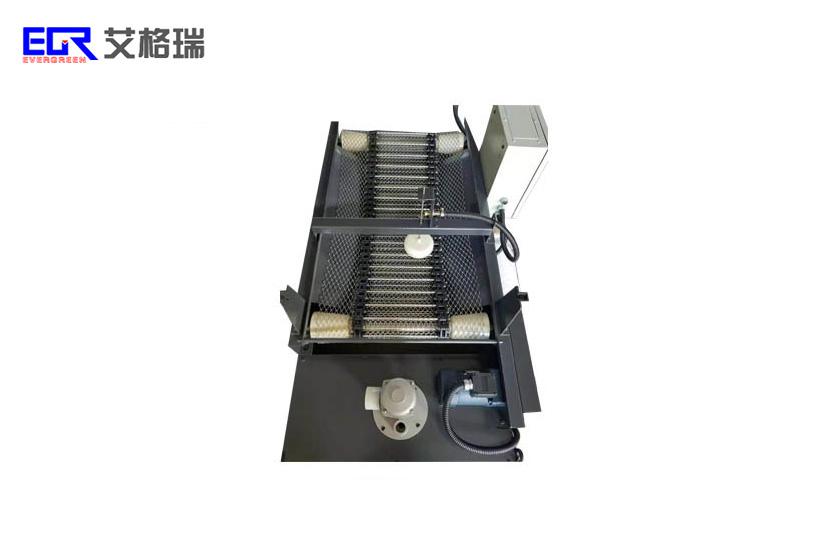

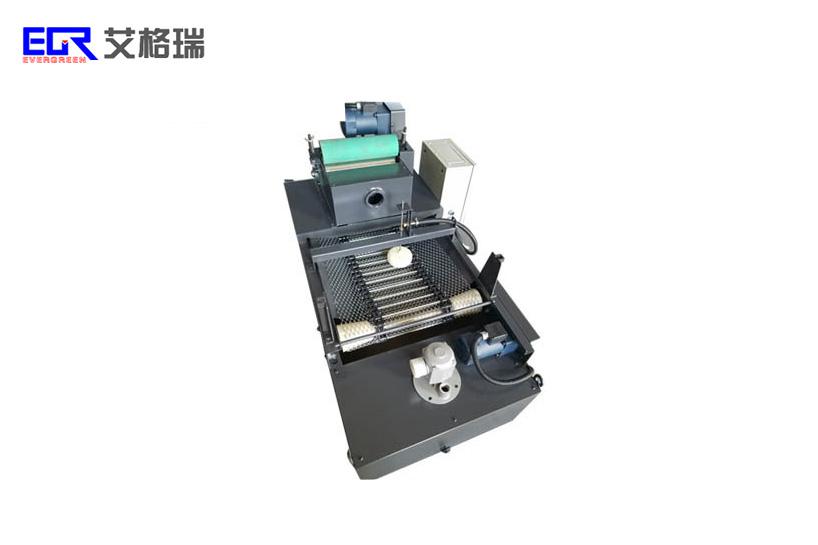

The EGRWF vortex separator uses a certain pressure to inject liquid containing particle impurities into the cone at high speed along the tangential direction from the inlet, and performs a spiral motion from top to bottom, causing the liquid to generate an external vortex inside the cone. The solid particles in the liquid are thrown towards the inner wall of the cone under the action of centrifugal force, and are discharged along the inner wall through the bottom flow port under the drive of gravity and liquid. The separated clean liquid reaches the bottom of the cone and spirals up along the axis of the cone, forming an internal vortex, which is discharged from the outlet of the vortex separator, thus achieving the separation of dirty liquid and clean liquid. The separation accuracy is high, and 98% of particles over 30 μ can be separated.

Purpose:

Eddy current separators are mainly used to separate small particles in liquids, suitable for separating particles in high-speed grinding, strong grinding, general precision machining emulsions, and low viscosity oil-based cutting fluids.

Performance:

Clean cutting fluid can extend the service life and reliability of cutting tools, improve the machining quality of parts, prevent cutting fluid from deteriorating, and extend its service life. Can be used in parallel to increase flow.