Current Location:HOME > Products > Filter and chip removal accessories

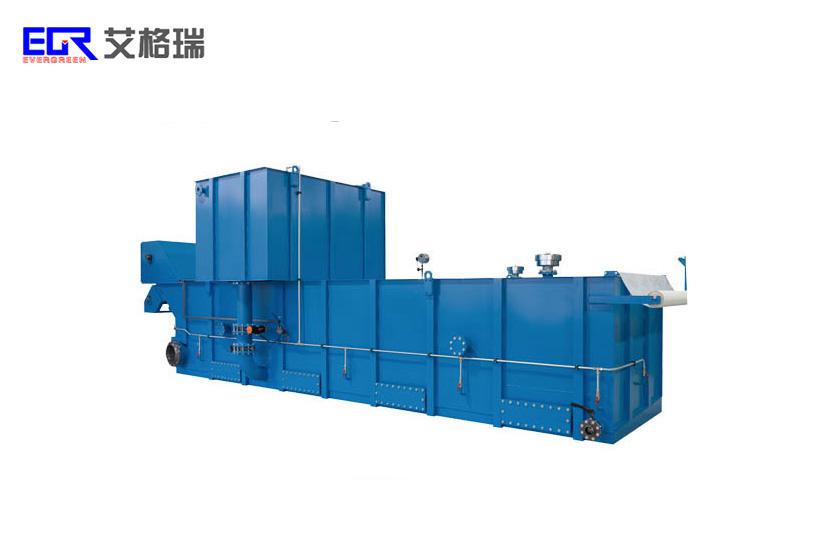

CF series magnetic separator

With its excellent performance, it has won high recognition in the market

-

Time:2025-05-04 12:49

-

Category:Filter and chip removal accessories

-

Application:Used for purifying coolant (cutting oil or emulsion) for grinding machines and other machine tools. By using the magnetic drum of the separator, the iron filings in the coolant are sucked out to keep the coolant dry.

-

+86-0535-6529899 (Hotline)

Details

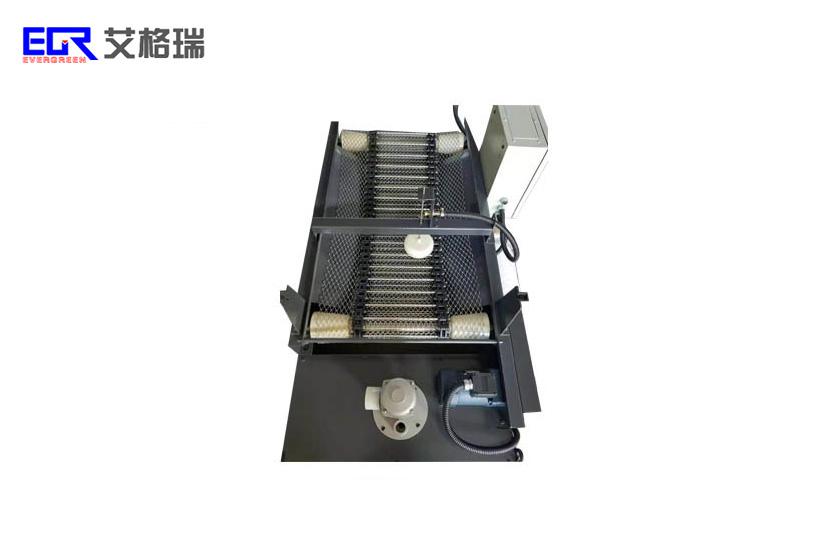

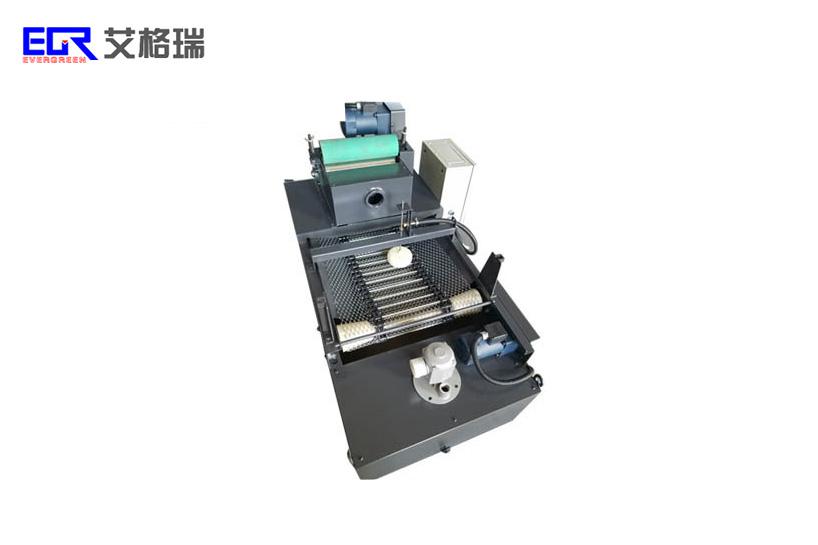

The EGRCF magnetic separator consists of several parts, including a reducer, a box, magnetic rollers, rubber rollers, and a scraper plate. The reducer drives the magnetic roller to rotate. After the coolant enters the box, ferromagnetic impurities are adsorbed on the outer wall of the magnetic roller. After being crushed by the rubber roller, the liquid carried by the impurities is squeezed out. Finally, a scraper plate separates the impurities from the magnetic roller. This device has a simple appearance, small size, and is easy to install and use. It is an important accessory for grinding machines and automatic grinding lines.

Purpose:

Used for purifying coolant (cutting oil or emulsion) for grinding machines and other machine tools. By using the magnetic drum of the separator, the iron filings in the coolant are sucked out to keep the coolant dry.

effect:

The use of magnetic separators can reduce the number of grinding wheel corrections, improve the surface smoothness of workpieces, and extend the service life of grinding wheels and coolant. At the same time, it reduces the labor intensity of workers and minimizes the environmental pollution caused by coolant.

matters needing attention:

When not working for a long time, the box should be cleaned to prevent impurities from forming.

2. A flow rate greater than the set working flow rate will affect the separation effect.

3. Not applicable to coolant containing steel shavings.

4. If there are too many impurities in the coolant, the gap between the rubber roller and the outer wall of the magnetic roller should be adjusted, otherwise it will cause an increase in the height of impurities on the outer wall of the magnetic roller, making it impossible to pass through the area being rolled by the magnetic roller.

5. The inlet form can be designed according to customer requirements.

In grinding, with the improvement of machining accuracy, high-speed grinding and grinding technology have developed rapidly. In addition to selecting reasonable grinding parameters, it is also necessary to improve the circulation quality of grinding fluid. Purification devices are divided into two types: filtration type and power type. Power type separators rely on certain forces (such as centrifugal force, magnetic force, or gravity) to separate impurities, such as centrifugal, vortex, and magnetic separators. Filter type filters rely on filter media to separate impurities, such as filter screen type, line gap type, sheet type, and paper tape type filters.

When grinding ferromagnetic materials, the waste liquid contains both ferromagnetic substances and non ferromagnetic impurities. Generally, a magnetic separator is used to remove more than 80% of the impurities. For better control of filtration accuracy, it is recommended to use a combination of magnetic separator and paper tape filter.

characteristic

1. The transmission system is separated from the casing, making cleaning and maintenance convenient.

2. The magnetic roller is evenly magnetized, and the separated debris and iron powder are dried.

3. Magnetic separators can handle coolant containing powdery magnetic impurities.

4. The generated magnetic field is large, and the stainless steel magnetic roller has a large adsorption area and good separation effect.

5. Simple appearance, compact structure, smooth operation, low noise, and low power loss.

6. Small size, easy to install and use, can be designed and manufactured according to the specific space of the machine tool.